Value Engineering

Grow Project Value and Improve Profits Using Value Engineering (VE)

Value Engineering is a time-tested, proven methodology to dramatically improve designs and processes in a wide range of industries and applications. VE is delivered in a team setting, and follows the SAVE International sequence from initial framing through to high-value results delivery.

www.value-eng.org

How does Value Engineering work?

Value Engineering identifies areas of improvement in designs and processes, looking at cost, speed of execution, quality and performance. It’s a highly focused effort that answers two fundamental questions:

- What functions are being performed, and

- How else can we perform these functions to improve value?

The Value/Cost Balance:

Value Engineering is NOT cost cutting. Value to you and your customers is improved when the same functions are provided at a lower cost, or more functionality is delivered at the same cost, thus:

How is Value Engineering delivered?

Value Engineering is a team process typically running 3 to 5 days. Through query, exploration, mapping and modeling, workshops uncover alternative solutions that would otherwise not be apparent. Your team will develop specific recommendations and a realistic plan of action.

Who takes part in Value Engineering?

Orlean Technical Solutions facilitates intensive group sessions involving key players within your organization, including engineers, technical and operational experts, cost coordinators and often a credible outside expert.

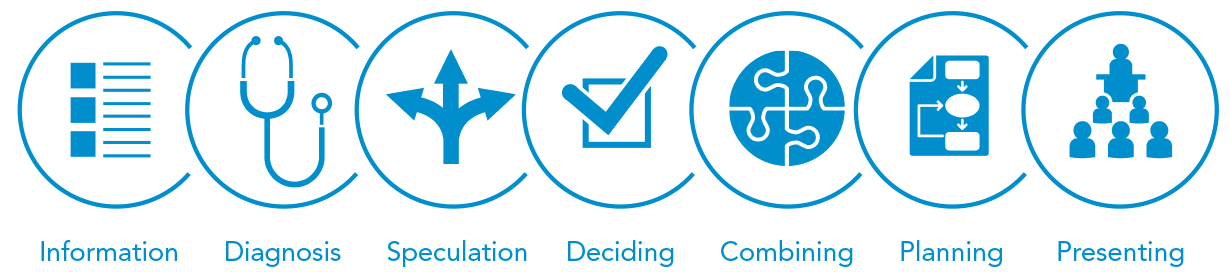

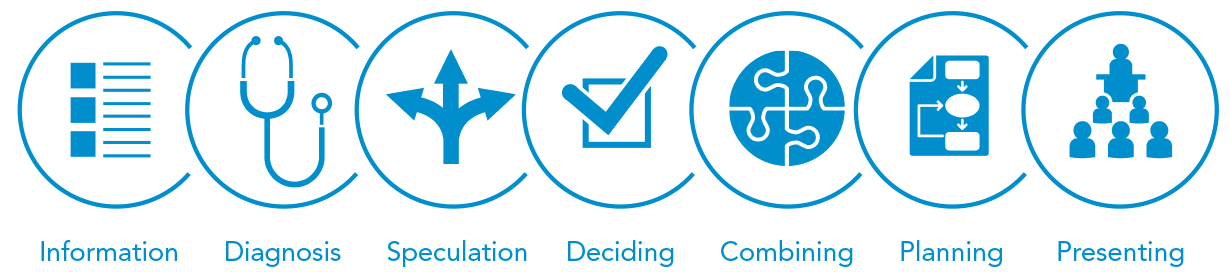

Seven Steps to Value Engineering

Phase 1: Information

Define the problem and expected goals. Answers the question: What functions are being performed?

Phase 2: Diagnosis

Assign a cost, rank and value to each function to identify areas of improvement.

Phase 3: Creative Innovation

Use creative thinking techniques to generate a broad list of ideas to solve the problem.

Phase 4: Analysis

Scrutinize, discuss and evaluate ideas resulting in a well-defined list of viable alternatives.

Phase 5: Combining

Merge the most promising ideas into concepts, which are further evaluated against desired attributes.

Phase 6: Planning

Develop implementation plans that address both technical and non-technical issues, including costs, materials, procedures, design and scheduling.

Phase 7: Presenting

Prepare and present recommendations to key decision-makers, supported by a detailed written proposal.

Each workshop is enabled by data handling and transfer software that un-burdens participants of mundane tasks, focusing their energies to maximize the contribution from their time commitment.

What kind of results can I expect?

Typical cost-focused studies result in cost reductions of 10-20%, with client yield payouts of at least 50:1 on their Value Engineering investment.

What can be Value Engineered?

Value Engineering can be applied to a wide range of challenges, from single components or sub-systems to complex processes and projects.

Value Improving Practices

Value Improving Practices or VIPs have become a standard part of major project executions. Beyond delivering the Value Engineering VIP, we can also lead you through several other VIPs in a single sitting — satisfying your decision stage-gate requirements in a compact, yet rigorous way, including:

- Design to Capacity

- Constructability

- Technology Selection

- Process Simplification

Timing and Delivery of Value Engineering Process

- VE is most potent when applied early in a project, before concepts are fully defined and opportunities for improvement are large.

- Later in the project life-cycle, VE